OUR SERVICES

We take great pride in our ability to manufacture high quality mouldings in nearly any specie of wood. Most any profile can be duplicated with our modern moulding machinery. If we don't have it in stock we can custom make it.

HOW WE MAKE A CUSTOM MOULDING PROFILE

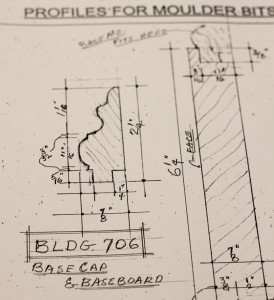

A customer brings us a sample or detailed drawing of what they need ... in this case, a sample of base cap from a 120 year old home.

From the sample provided we draft a detailed drawing.

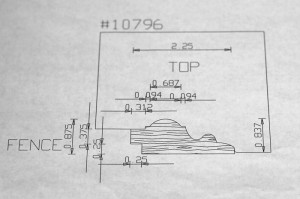

A CAD(computer-aided design) drawing is created from the detailed drawing.

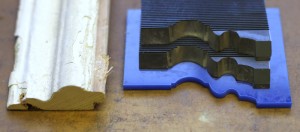

From the CAD drawing a plastic template is cut. The plastic template is used to grind high-speed steel into moulding cutters that will be used in our Weinig moulders.

The steel cutters are installed into a moulder head.

The heads are fitted to one of our Weinig moulders and the process is nearly complete.

The selected specie and appropriately sized wood is fed into the moulder.